What Are Lab Drying Ovens? And What Are They Used For?

Lab Drying Ovens are fundamental equipment in modern laboratories as they play an important role in ensuring the accuracy and efficiency of numerous laboratory procedures. From drying glassware and sterilizing equipment to conducting controlled heating experiments, these devices hold great importance in the lab.

What are Lab Drying Ovens?

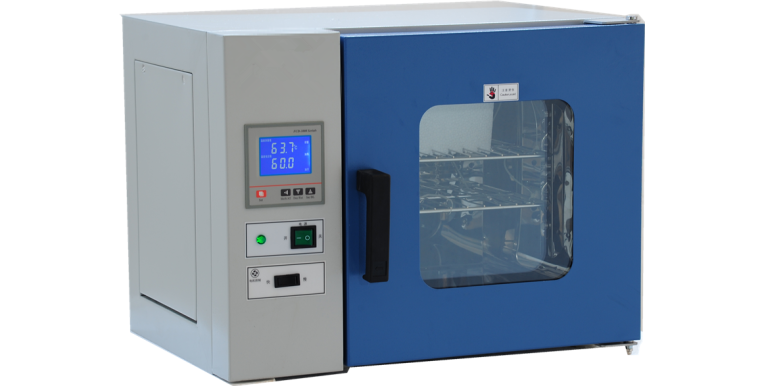

Laboratory drying ovens are specialized devices used in laboratories for the purpose of removing moisture from samples, maintaining temperature uniformity, and ensuring sample integrity

Laboratory drying ovens are available in four sizes, ranging from 8 to 36 cubic feet, specially made to accommodate various laboratory requirements. These ovens are carefully designed to handle a multitude of applications, such as baking, drying, preheating, or any other task that requires a reliable source of air heated up to 850°F.

Unique Features Of Lab Drying Ovens

Laboratory drying ovens come with various features designed to ensure reliable, accurate, and efficient operation. Here are some of the most common features found in lab ovens.

Effective Temperature Control

Lab ovens come equipped with precise temperature control systems. Depending on the model, they can typically operate from ambient temperature up to a specific maximum. High-temperature lab ovens can reach temperatures of 500°C (932°F) or higher.

Uniform Heat Distribution

Lab ovens are designed to provide uniform heat distribution throughout the interior space so that consistent results are ensured.

Diverse Capacity Options

Lab ovens come in various sizes to accommodate different laboratory needs. They can vary from compact benchtop models to larger, freestanding units.

Adjustable Shelving

Many oven models come with adjustable shelving to provide flexibility in arranging the interior space according to the needs of the specific experiment or process.

Digital Display

Lab ovens often feature a digital display that facilitates easy monitoring and setting of temperature, time, and other operational parameters.

Safety Features

Lab ovens typically include safety features such as over-temperature protection to prevent overheating, and often have insulated exteriors to protect users from burns.

Durable and Heat Resistant Material

These ovens are usually built from robust materials that can withstand high temperatures and repeated use. Stainless steel is a common choice for its durability and resistance to rust and contamination.

Low Maintenance

Lab ovens are often designed with removable or easy-to-clean components to keep them clean and free from contamination.

Certifications Accepted Worldwide

Many lab ovens come with certification from recognized bodies like ISO or ASTM,. These certifications portray that the lab oven model meets international standards for quality and safety.

These features collectively contribute to lab drying ovens' performance, reliability, and user-friendliness and make them indispensable tools in many scientific and industrial settings.

Importance of Lab Drying Ovens

Laboratory drying ovens are integral to various scientific and industrial procedures due to their ability to maintain precise, controlled temperatures and their capability to handle a broad spectrum of applications.

The precise temperature control in these ovens allows for reliable and repeatable results, a critical factor in any experimental setting. Their versatility in application, ranging from drying glassware and sterilizing equipment to sample drying and heat treatment, makes them a central object in many laboratories.

They also boast essential safety features, which prevent overheating and other potential hazards, providing a secure environment for heat-related processes.

Standard Protocols to Ensure When Using Lab Drying Ovens

Here are some standard protocols for operating the lab equipment for all types of drying oven. One must follow these standards to ensure the safety of the workers and work premises.

Inspection Prior to Use

Before using a lab drying oven, it is important to inspect the oven for any damage or issues that might compromise safety or efficiency.

Verification of Temperature Settings

Setting the correct temperature is crucial for the task at hand. Most lab ovens have a temperature range between ambient temperature and 250°C1, although some high-temperature ovens can reach up to 500°C maximum.

Appropriate Sample Preparation

Samples should be prepared and placed correctly within the oven to ensure even heat distribution. Overcrowding should be avoided as it can adversely affect the accuracy of results.

Take Precautionary Safety Measures

Always wear heat-resistant gloves when handling items within the oven. It is important to keep flammable and volatile substances away from the oven.

Ensure Regular Maintenance

Regular maintenance of the oven is necessary to ensure it remains in good working order. This includes cleaning the interior after use and regularly checking the temperature calibration.

Check Compliance with Relevant Guidelines

It is important to ensure all procedures related to the lab drying oven comply with your laboratory's Health and Safety guidelines and any industry-specific regulations.

Uses of Different Lab Drying Oven Types

Drying ovens are used in a variety of industries and for numerous applications, each with their unique requirements. Here's how the uses differ for pharmaceutical, standard, and lab ovens.

Pharmaceutical Drying Ovens

These ovens are specifically used in the pharmaceutical industry and are designed to adhere to the strict guidelines and standards set by regulatory bodies such as the FDA. Pharmaceutical ovens are often used for sterilizing, depyrogenation (removing pyrogens), and drying pharmaceutical products.

Moreover, Drying oven for pharmaceutical also plays a vital role in processes such as granulation and coating, and the drying of soft and hard capsules, powders, and other pharmaceutical formulations. The key characteristic of pharmaceutical ovens is their ability to maintain uniform temperature and humidity levels, which is critical for ensuring the consistency and quality of drug products.

Standard Oven

It is often referred to as an industrial oven and is one of the main laboratory equipment. These ovens are used for a wide range of applications across many industries, not limited to scientific or pharmaceutical applications.

A standard oven might be used for drying, curing, baking, pre-heating, burn-off, and other heat-treating processes. Its uses can range from drying automotive parts to baking ceramics.

Laboratory Ovens

These ovens are specially designed for use in a laboratory setting, with applications spanning various scientific disciplines. The laboratory oven uses include employing them for processes such as drying glassware, sterilizing equipment, performing heat treatment and thermal testing, and drying samples.

These lab ovens often come equipped with precise temperature controls to ensure accurate and repeatable results in experiments. They need to adhere to the standards set by scientific bodies and might be used in fields such as biology, chemistry, physics, and materials science.

Westlab Canada is the best lab supplies online for various scientific equipment. Here we offer a variety of operational tools with 100% efficiency and reliability in work. Go and check our website for maintaining your lab with the advanced scientific technology.